Intercooler piping is a critical component in high-performance vehicles, enhancing engine efficiency and throttle response by ensuring optimal air density. Efficient design features smooth curves, minimal restrictions, and specialized fittings for swift airflow, boosting system-wide performance. Modern approaches leverage strategic engineering, advanced manufacturing techniques, and seamless integration with intake components to deliver unparalleled intercooler piping efficiency, resulting in enhanced engine performance and fuel economy.

Intercooler piping, a critical component in high-performance engines, plays a pivotal role in enhancing power output and engine efficiency. This article delves into the intricacies of intercooler piping design, offering insights on maximizing flow efficiency. From understanding fundamental principles to exploring advanced techniques, we unravel the key factors ensuring optimal performance. Discover how expertly crafted piping systems revolutionize cooling, boosting engine capabilities in demanding applications.

- Understanding Intercooler Piping Basics

- Key Factors for Optimal Flow Design

- Advanced Techniques for Maximum Efficiency

Understanding Intercooler Piping Basics

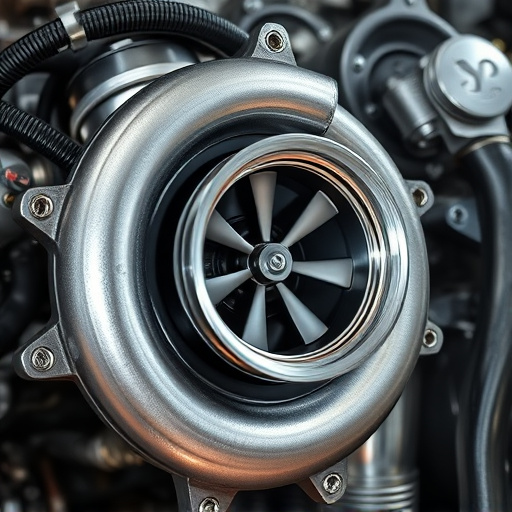

Intercooler piping is a critical component in any high-performance vehicle’s cooling system, designed to enhance engine efficiency and throttle response. It acts as the pathway for compressed air to travel from the turbocharger or supercharger to the intercooler, where it’s cooled before entering the engine. This direct route minimizes temperature rise, ensuring optimal air density and power output.

Understanding intercooler piping basics involves recognizing its role in maintaining efficient airflow. Well-designed piping features smooth curves and minimal restrictions, allowing for swift movement of cool air. Additionally, incorporating components like high-flow reducers or specialized fittings can further enhance flow efficiency. This is particularly relevant when paired with performance air filters and cold air intakes, as these suspension kits contribute to drawing in cooler, denser air, which the efficient intercooler piping then delivers to the engine for improved performance.

Key Factors for Optimal Flow Design

The design of intercooler piping plays a pivotal role in achieving maximum flow efficiency within an automotive cooling system. Key factors for optimal flow design include ensuring low pressure drop, smooth and continuous contours, and efficient heat transfer. By minimizing restrictions in the piping network, high-performance parts can operate at their peak capabilities, allowing for enhanced engine performance and improved fuel efficiency.

Additionally, seamless integration with intake components and air filter kits is essential. Well-designed intercooler piping facilitates the uninterrupted flow of cool air to the engine, enhancing the overall efficiency of the entire system. This synergy between intercooler piping, high-performance parts, and intake components contributes to a more responsive and powerful vehicle performance.

Advanced Techniques for Maximum Efficiency

In the pursuit of maximum flow efficiency for intercooler piping, advanced techniques have emerged that transcend conventional design. These innovations extend beyond simple material choices and include sophisticated engineering strategies. For instance, seamless integration of intercooler piping with high-performance coilover kits allows for optimized cooling solutions, enhancing engine responsiveness and power output. Furthermore, meticulously designed intake components and suspension components play a pivotal role in ensuring consistent air flow, thereby maximizing the intercooler’s effectiveness.

Specialized manufacturing processes, such as precision laser cutting and advanced welding techniques, contribute to minimizing restrictions in the piping system. These methods enable smoother, more unrestricted airflow, enhancing overall performance. By combining these advanced techniques with carefully selected materials, modern intercooler piping systems offer unparalleled efficiency, ensuring that engine-generated power is channeled effectively for optimal vehicle dynamics—a true testament to engineering prowess.

Intercooler piping, designed with precision and an understanding of fluid dynamics, is a key component in enhancing engine performance. By focusing on optimal flow design and employing advanced techniques, car enthusiasts can experience improved throttle response, increased power outputs, and more efficient cooling. These innovations in intercooler piping are truly revolutionizing the automotive landscape, ensuring that engines run cooler, perform better, and last longer.