Intercooler piping is a critical factor in high-performance engines, efficiently transporting cooled air from turbochargers to intercoolers, maintaining optimal temperatures, enhancing power output, and improving efficiency. Testing on a dynamometer (dyno) offers a controlled environment to measure precise power output and torque gains, crucial for maximizing horsepower. Optimizing dyno tests by controlling temperature and humidity, along with using high-quality sensors and strategic high-performance parts, ensures accurate assessment of intercooler piping modifications for an enhanced driving experience.

Intercooler piping, a critical component in engine cooling systems, plays a significant role in overall engine performance. To unlock its full potential and gain an edge in performance gains, many enthusiasts turn to dyno testing. This article delves into the intricacies of intercooler piping and highlights why dyno testing is essential for optimizing engine performance. By understanding the benefits and proper test optimization techniques, you can harness the power of intercooler modifications for improved engine output and efficiency.

- Understanding Intercooler Piping and its Role in Engine Performance

- The Benefits of Testing on a Dyno: Unlocking Hidden Potential

- Optimizing Dyno Tests for Intercooler Piping Modifications

Understanding Intercooler Piping and its Role in Engine Performance

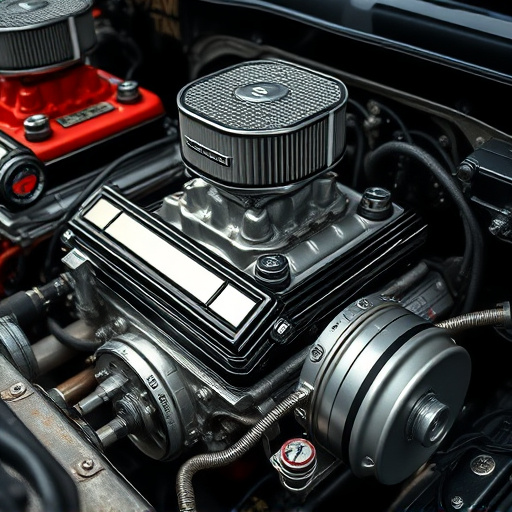

Intercooler piping is a critical component in any high-performance engine setup. It facilitates the efficient transfer of compressed air from the turbocharger to the intercooler, ensuring optimal cooling before entering the engine. This process is crucial for maintaining engine temperatures, enhancing power output, and improving overall efficiency. A well-designed intercooler piping system can significantly impact an engine’s performance, especially when combined with other modifications like cat back exhausts and coilover kits or suspension kits.

The role of intercooler piping goes beyond just cooling the air. It also plays a vital role in minimizing heat loss and pressure drop, ensuring that the engine receives a consistent supply of cool, dense air. This is particularly important in high-boost applications where even minor inefficiencies can lead to significant performance gains. By optimizing the intercooler piping, users can better leverage the power potential of their engines, complementing upgrades like suspension kits for a more balanced and responsive driving experience.

The Benefits of Testing on a Dyno: Unlocking Hidden Potential

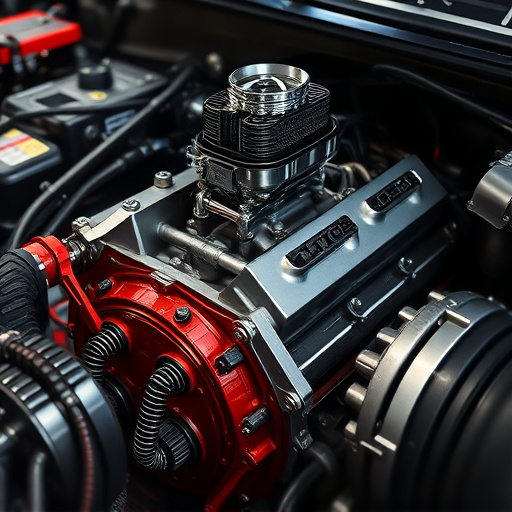

Testing intercooler piping on a dyno offers an unparalleled opportunity to unlock hidden performance potential in any vehicle. Unlike road testing, where variables like traffic, weather, and varying terrain can skew results, a dynamometer provides a controlled environment. This ensures accurate measurements of power output and torque at the wheels, directly correlating with engine performance. By simulating real-world driving conditions while isolating external factors, dyno testing allows for precise adjustments to intercooler piping, enhancing efficiency and maximizing horsepower gains.

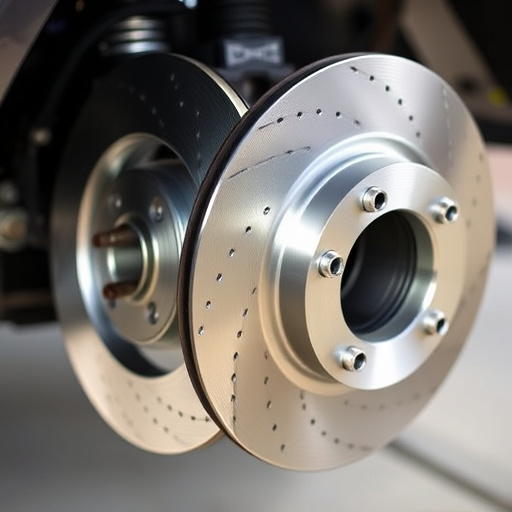

Furthermore, integrating data from dyno tests into a vehicle’s overall tuning strategy is invaluable. Analyzing flow rates, pressure differentials, and cooling efficiency enables tuners to fine-tune not only the intercooler piping but also other critical components like brake rotors, suspension parts, and exhaust systems, creating a harmonious synergy that contributes to overall performance improvement. This holistic approach ensures that each modification complements the others, resulting in a more powerful, responsive, and ultimately, more enjoyable driving experience.

Optimizing Dyno Tests for Intercooler Piping Modifications

To maximize gains from intercooler piping modifications, optimizing dyno tests is key. It’s crucial to control variables like ambient temperature and humidity, as these factors can significantly impact boost levels and engine performance. The setup should focus on simulating real-world driving conditions while capturing precise data on airflow, pressure drop, and temperature changes. This involves careful calibration of the dyno itself, along with using high-quality sensors and measurement tools to ensure accuracy.

Additionally, integrating intake components and muffler tips designed for optimal airflow can enhance test results. By employing high performance parts that promote efficient air flow, you can better assess the full potential of intercooler piping modifications. This strategic approach ensures that any gains attributed to intercooler upgrades are accurately measured and verified on the dyno, providing a solid foundation for further tuning and optimization.

Intercooler piping, a crucial component in engine performance, can significantly enhance power and efficiency. Testing on a dyno provides an invaluable platform to optimize these modifications, allowing for precise adjustments to maximize gains. By understanding the dynamics of intercooler piping and leveraging dyno testing, enthusiasts and professionals alike can unlock hidden potential in their vehicles, resulting in improved performance and a more satisfying driving experience.