Intercooler piping is a crucial element in high-performance vehicles, optimizing airflow dynamics by cooling and delivering compressed intake air from turbochargers or superchargers. Its meticulously designed layout minimizes turbulence, ensuring consistent airflow to the engine's combustion chamber. This enhances power output, improves fuel efficiency, and reduces wear on components. Key benefits include better acceleration, improved fuel economy, and enhanced driving dynamics, achieved through controlled air circulation facilitated by advanced engineering in intercooler piping design.

Intercooler piping is a critical component in automotive cooling systems, playing a pivotal role in engine performance. This article delves into the intricate dynamics of intercooler piping and its profound effect on airflow. We explore how turbulence, often considered a hindrance, can be mitigated through optimized piping design, leading to smoother air flow and enhanced engine efficiency. Understanding these principles offers valuable insights for automotive engineers striving to achieve peak engine performance.

- Understanding Intercooler Piping and Its Role in Airflow Dynamics

- The Impact of Turbulence on Engine Performance and Efficiency

- How Optimized Piping Design Can Streamline Airflow for Better Results

Understanding Intercooler Piping and Its Role in Airflow Dynamics

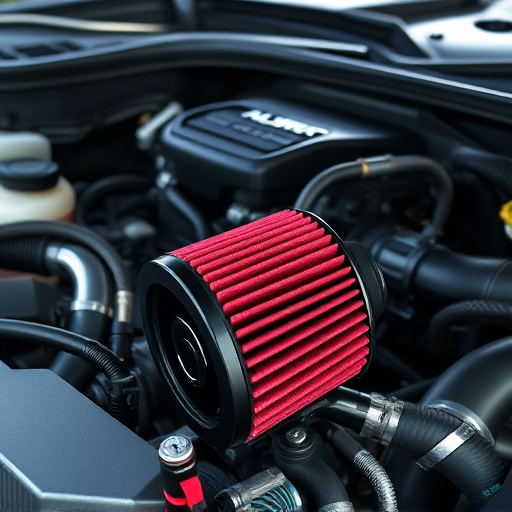

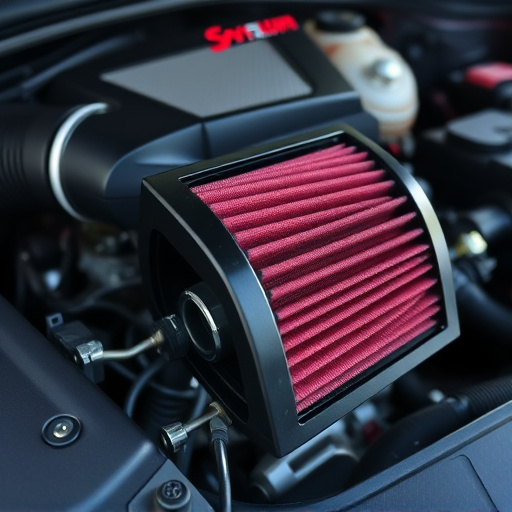

Intercooler piping, a critical component in many high-performance vehicles, plays a pivotal role in managing airflow dynamics within the engine bay. These pipes are designed to cool compressed air from the turbocharger or supercharger before it enters the engine’s combustion chamber. By reducing the temperature of the intake air, intercoolers prevent excessive heat build-up, ensuring optimal performance and efficiency.

The design of intercooler piping is as intricate as the engineering behind brake rotors and suspension components. Smooth, contoured paths are engineered to minimize turbulence, allowing air to flow seamlessly. This reduces pressure drops across the system, resulting in a more consistent and controlled airflow supply to the engine. Efficient intercooler piping complements the performance of intake components, ensuring that the engine receives cool, dense air for enhanced power output and fuel efficiency.

The Impact of Turbulence on Engine Performance and Efficiency

Turbulence, or chaotic airflow, within an engine can significantly impact its performance and efficiency. When air doesn’t flow smoothly through an engine’s components, it creates pressure differentials and increases friction, leading to reduced power output and higher fuel consumption. This is particularly evident in high-performance vehicles where optimal airflow is crucial for achieving maximum horsepower and torque. Intercooler piping plays a vital role in minimizing turbulence by ensuring cool, dense air efficiently reaches the engine, enhancing overall engine management.

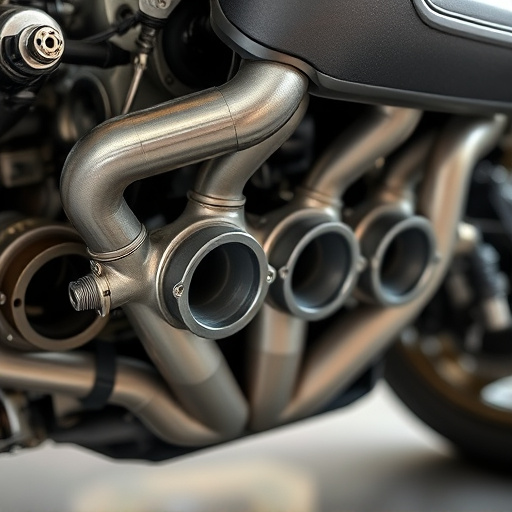

In addition to intercooler piping, other modifications like performance air filters and suspension kits can further contribute to smoother airflow. While exhaust mufflers primarily focus on noise reduction, they also help maintain a consistent air flow, preventing backpressure that could hinder engine performance. By addressing turbulence at multiple points, vehicle owners can experience improved acceleration, better fuel economy, and enhanced overall driving dynamics.

How Optimized Piping Design Can Streamline Airflow for Better Results

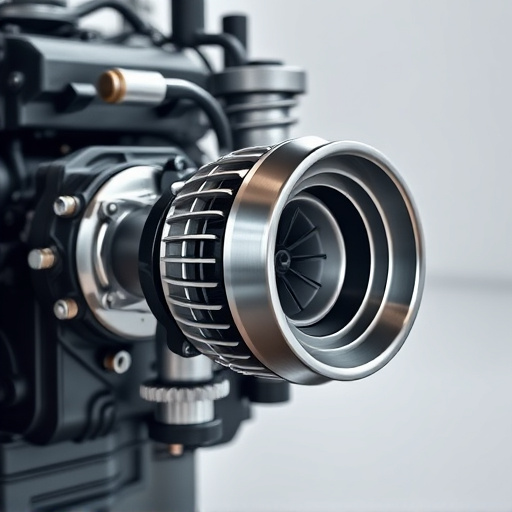

Optimized intercooler piping design plays a pivotal role in enhancing airflow performance within an engine system. By implementing strategic layouts and incorporating advanced engineering principles, engineers can achieve smoother and more efficient air circulation. This streamlined process ensures that cool air reaches the combustion chamber optimally, fostering enhanced engine output and reduced turbulence.

Such design innovations often involve carefully crafted curves, reduced diameters at crucial points, and strategically placed exhaust tips to minimize pressure drops. These techniques allow for a seamless transition of air from the cold air intakes into the intercooler and subsequently to the engine. This not only boosts engine efficiency but also reduces the wear on components like brake pads due to lower stress levels caused by turbulent airflow.

Intercooler piping, by reducing turbulence and optimizing airflow dynamics, plays a pivotal role in enhancing engine performance and efficiency. The article has highlighted how intricate pipe designs can significantly streamline air circulation, leading to better engine outputs. By understanding the impact of turbulence and employing strategic piping solutions, engineers can achieve smoother, more efficient airflow, ultimately benefitting various industries that rely on powerful and reliable engines. This focus on intercooler piping design is a testament to continuous efforts in refining automotive and industrial systems.