Intercooler piping, vital for high-performance vehicles, facilitates efficient heat transfer, enhances airflow and minimizes pressure drop. Optimized design with appropriate material choices improves throttle response, horsepower and fuel efficiency. Advanced engineering techniques using lightweight alloys and specialized components further enhance flow efficiency, benefiting vehicle dynamics and driver experience.

Intercooler piping, a critical component in high-performance vehicles, plays a pivotal role in maximizing engine efficiency and cooling. This article delves into the intricacies of intercooler design, focusing on how optimal piping can enhance airflow and reduce temperature, leading to improved engine output. From understanding basic principles to exploring advanced techniques, we uncover key factors for achieving maximum flow efficiency in intercooler systems.

- Understanding Intercooler Piping Basics

- Key Factors for Optimal Flow Design

- Advanced Techniques for Maximum Efficiency

Understanding Intercooler Piping Basics

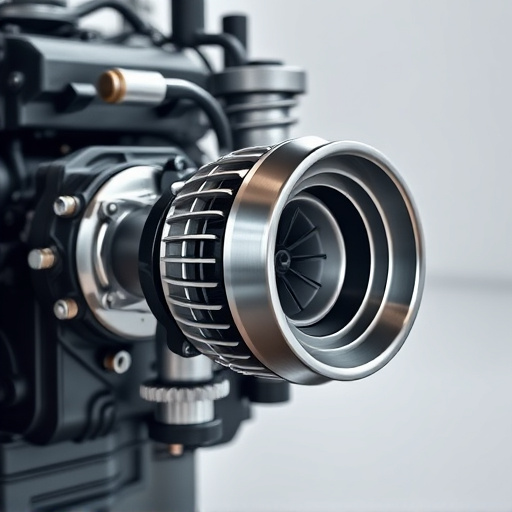

Intercooler piping is a critical component in high-performance vehicles, especially those with turbocharged or supercharged engines. It facilitates the efficient transfer of heat from the engine to the intercooler, ensuring optimal air induction temperatures. The system comprises a network of tubes and fittings designed to maximize airflow while minimizing pressure drop, thereby enhancing overall engine performance.

Understanding the basics of intercooler piping involves grasping how it interacts with other components like exhaust muffler tips and exhaust systems. Properly engineered piping allows for seamless integration, enabling efficient cooling without compromising exhaust gas flow. This, in turn, contributes to improved throttle response, horsepower output, and fuel efficiency, making it a crucial element for both stock and modified vehicles.

Key Factors for Optimal Flow Design

The design of intercooler piping plays a pivotal role in achieving maximum flow efficiency within an automotive cooling system, particularly for high-performance vehicles. Key factors that influence optimal flow include pipe diameter and length, as well as the number and placement of bends and connections. Larger diameters reduce resistance, ensuring faster and more efficient fluid movement, while minimizing sharp bends helps to maintain pressure and velocity.

Furthermore, selecting the right materials is crucial, considering both weight and heat conductivity. Lightweight alloys, such as aluminum, offer reduced overall vehicle weight, contributing to improved performance. In contrast, high thermal conductivity materials expedite heat transfer from the intercooler to the surrounding air, enhancing cooling efficiency. Integrating these design considerations seamlessly with other critical brake components and performance exhaust systems can significantly impact overall vehicle dynamics and driver experience, resulting in both enhanced performance and durability.

Advanced Techniques for Maximum Efficiency

In the pursuit of maximum flow efficiency for intercooler piping, advanced techniques play a pivotal role. Beyond basic design considerations, engineers are leveraging cutting-edge materials and innovative construction methods to minimize pressure drop and optimize air flow. High-flow, low-restriction pipes, crafted from lightweight yet durable alloys, significantly enhance the overall performance of the cooling system.

Furthermore, integration of specialized intake components, such as high-performance air filters and meticulously engineered turbulators, contributes to improved airflow dynamics. These components not only capture finer particles but also create a smoother, more turbulent air stream, ensuring optimal gas exchange within the intercooler core. Additionally, performance brakes tailored for intercooler systems help regulate temperature more effectively, allowing for enhanced engine performance and efficiency across diverse operating conditions.

Intercooler piping, designed with a deep understanding of fluid dynamics and advanced engineering techniques, is crucial for maximizing flow efficiency in automotive systems. By considering factors like pipe diameter, bend radius, and strategic placement, engineers can optimize cooling performance, ensuring engines run at their peak. With continuous advancements in materials and designs, the future of intercooler piping promises even greater flow efficiency, enhancing overall vehicle performance and fuel economy.