Intercooler piping leaks in turbocharged/supercharged vehicles stem from corrosion, worn gaskets, or road debris. They cause performance issues, including reduced horsepower, poor drivability, and increased fuel consumption. Regular maintenance, quality components, and rigorous testing prevent these leaks, ensuring optimal engine efficiency and turbo/supercharger longevity.

Intercooler piping, crucial for optimal engine performance, must be leak-free. Leaks in these vital systems can significantly impact efficiency, leading to reduced power output and increased fuel consumption. This article delves into the causes and consequences of intercooler piping leaks, highlighting their effect on engine performance. We also explore maintenance practices and testing methods to ensure leak-free systems for optimal vehicle operation. Understanding these factors is essential for both professionals and enthusiasts alike.

- Understanding Intercooler Piping Leaks

- Impact of Leaks on Performance and Efficiency

- Maintenance and Testing for Leak-Free Piping Systems

Understanding Intercooler Piping Leaks

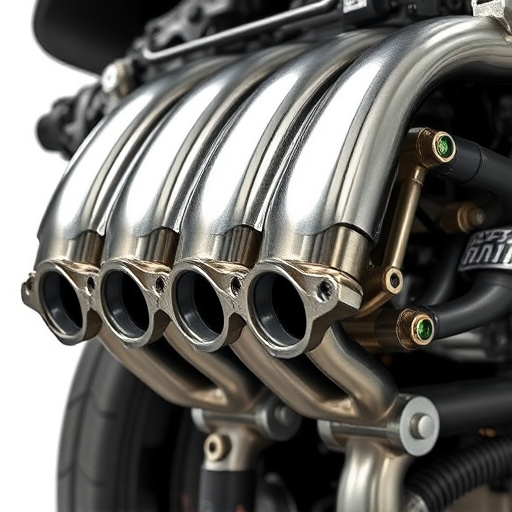

Intercooler piping leaks can be a significant issue for any vehicle with a turbocharged or supercharged engine. These leaks occur when there’s a breach in the sealed system that connects the intercooler to the intake components, allowing compressed air to escape, and potentially reducing engine performance. Over time, various factors like corrosion, worn-out gaskets, or damage to the pipes from road debris or accidents can contribute to these leaks.

Identifying intercooler piping leaks is crucial as they can manifest in unusual noises, reduced engine power, and even poor drivability. A vehicle’s performance exhaust system may also be affected, leading to muffler tips becoming rusted or damaged. Regular maintenance checks, especially on high-performance vehicles, can help prevent such issues. Using quality components during installation or repairs ensures the intercooler piping remains leak-free, thereby optimising engine efficiency and overall vehicle performance.

Impact of Leaks on Performance and Efficiency

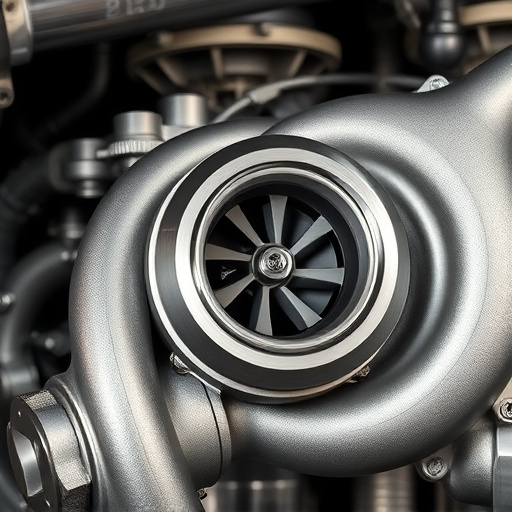

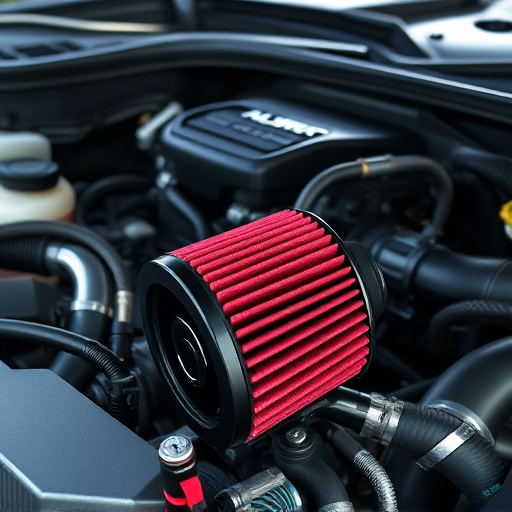

Leaks in intercooler piping can significantly impair both performance and efficiency. When an intercooler experiences a leak, it reduces the overall cooling capacity of the system, leading to elevated engine temperatures during high-performance scenarios. This can result in decreased horsepower output and increased fuel consumption as the engine works harder to maintain optimal operating temperatures. Moreover, leaks allow heated air to bypass the cold air intake and air filter kits, diminishing their effectiveness and further impacting engine performance.

Over time, persistent intercooler leaks can cause not only a loss of power but also premature wear on other components, such as turbochargers or superchargers. The reduced cooling efficiency can lead to increased strain on these parts, potentially reducing their lifespan. Therefore, maintaining leak-free intercooler piping is crucial for ensuring both peak performance and the longevity of high-performance automotive systems.

Maintenance and Testing for Leak-Free Piping Systems

Regular maintenance and rigorous testing are paramount to ensure intercooler piping remains leak-free. This involves periodic inspections for any signs of wear, corrosion, or damage, as well as pressure tests to verify the integrity of the system. Advanced diagnostic tools can help identify even subtle leaks that might go unnoticed during routine visual checks. These tests not only ensure optimal performance but also prevent potentially costly breakdowns caused by fluid leaks.

Additionally, incorporating high-quality materials and professional installation practices significantly reduces the likelihood of leaks. Modern intercooler piping systems often utilize advanced composites or lightweight metals known for their durability. Moreover, proper sealing techniques, including the use of specialized gaskets and sealants, play a crucial role in maintaining a leak-free environment. It’s equally important to consider the compatibility of replacement parts, such as exhaust muffler tips, with the existing intercooler setup to ensure long-term reliability.

Ensuring your intercooler piping remains leak-free is paramount for achieving optimal vehicle performance and efficiency. By understanding the causes of leaks, recognizing their impact on engine functionality, and implementing regular maintenance practices, you can prolong the lifespan of your intercooler system. Regular testing and proactive care are key to navigating the complexities of intercooler piping, ultimately enhancing both the reliability and power delivery of your high-performance vehicle.