Intercooler piping is a key element in high-performance vehicle cooling systems, strategically routing compressed air from turbochargers or superchargers to intercoolers for efficient temperature regulation. Optimized designs minimize pressure drops and maximize airflow efficiency, crucial when paired with performance upgrades like coilover kits or powerful brakes. Well-tuned intercooler piping enhances engine performance by allowing denser intake air and improved combustion, contributing to better vehicle handling and reliability under demanding conditions.

Intercooler piping is a critical component in automotive cooling systems, playing a pivotal role in managing efficient airflow. This essential system ensures optimal engine performance by rapidly reducing intake air temperature, enhancing combustion efficiency, and improving overall vehicle dynamics. Understanding the intricacies of intercooler piping design is key to unlocking its full potential, leading to better control and improved vehicle agility on the road. In this article, we explore the fundamental concept, key roles, and best practices for optimizing intercooler piping performance.

- Understanding Intercooler Piping: The Core Concept

- Key Roles of Intercooler Piping in Airflow Control

- Optimizing Performance: Best Practices for Intercooler Piping Design

Understanding Intercooler Piping: The Core Concept

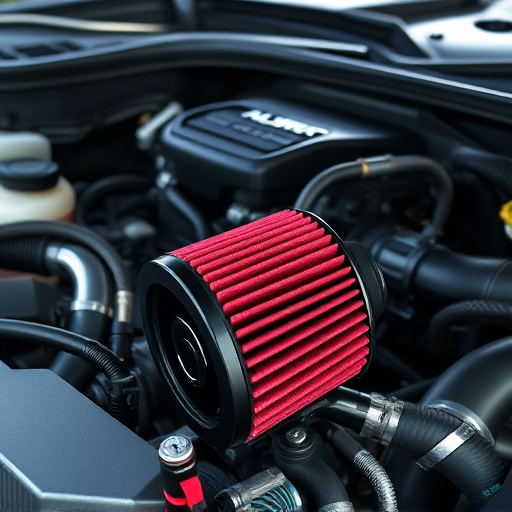

Intercooler piping is a critical component in vehicle cooling systems, especially for high-performance cars. It involves the strategic layout and design of tubes and connections that facilitate the flow of compressed air from the turbocharger or supercharger to the intercooler. This process is essential for efficient airflow control, ensuring optimal engine performance. By allowing for precise temperature regulation, intercooler piping plays a pivotal role in enhancing engine power and reducing turbulence within the system.

Understanding how intercooler piping functions is key to unlocking a vehicle’s true potential. The core concept revolves around minimizing pressure drop and maximizing airflow efficiency. Well-designed piping utilizes specific configurations, such as optimized bend radii and smooth internal surfaces, to ensure air flows smoothly through the system. This is particularly important when paired with performance upgrades like coilover kits or powerful brakes, which demand efficient cooling to maintain engine stability under high-stress conditions. Moreover, proper intercooler piping also considers aesthetic appeal, especially when customized exhaust tips are added, creating a visually striking and functional component.

Key Roles of Intercooler Piping in Airflow Control

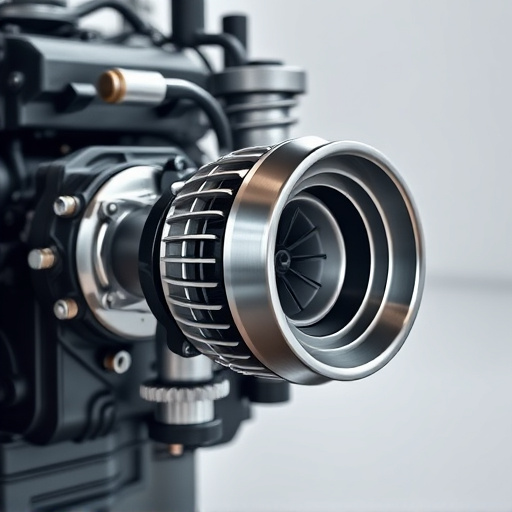

Intercooler piping plays a pivotal role in managing and controlling airflow within an engine system. These intricate networks of tubes facilitate the flow of cooled air from the intercooler to the engine, ensuring optimal performance and efficiency. By efficiently distributing chilled air, intercooler piping reduces temperature, allowing for denser intake air and improved combustion. This process is crucial, especially in high-performance exhaust systems, where heat can quickly build up, negatively impacting engine output.

Moreover, the design and layout of intercooler piping influence overall system efficiency. Strategically designed routing minimizes restrictions, enabling quick and unrestricted airflow. This is particularly beneficial when combined with top-tier brake components and suspension kits, as it enhances vehicle handling and response time by maintaining a cool and responsive engine under demanding conditions. The integration of advanced intercooler piping designs contributes to the overall performance and reliability of automotive systems.

Optimizing Performance: Best Practices for Intercooler Piping Design

Optimizing Performance: Best Practices for Intercooler Piping Design

Intercooler piping is a critical component in any high-performance vehicle or machinery, playing a pivotal role in managing airflow and enhancing overall efficiency. By meticulously designing and implementing best practices for intercooler piping, engineers can achieve significant improvements in engine performance, particularly under demanding conditions. This involves strategic routing, efficient diameter selection, and careful consideration of the impact on both intake air and exhaust systems.

A well-optimized intercooler piping setup ensures a balanced flow of air, minimizing restrictions and maximizing charge cooling capacity. This is crucial for maintaining optimal engine temperatures, boosting power output, and improving overall vehicle dynamics. Just as important, it reduces the strain on other components, such as brake pads and exhaust systems, contributing to longer-lasting performance and enhanced driver experience.

Intercooler piping is an integral component in optimizing engine performance and efficiency. By carefully designing and implementing best practices, as discussed in this article, engineers can ensure precise airflow control, leading to enhanced overall system functionality. Understanding the key roles of intercooler piping allows for the creation of robust systems that deliver optimal results, making it a crucial aspect for any automotive or engineering project focusing on efficient airflow management.