Intercooler piping, a vital component in forced induction systems, optimizes airflow and reduces temperature rise, leading to improved air density and turbine performance. Advanced designs with larger core sizes and efficient flow paths, coupled with high-quality materials like aluminum alloys, ensure quick cooling of compressed air for maximum combustion efficiency. Strategic routing and sizing of pipes minimize pressure drops, facilitating seamless airflow and preventing energy loss, ultimately enhancing engine power and performance, especially in high-performance vehicles.

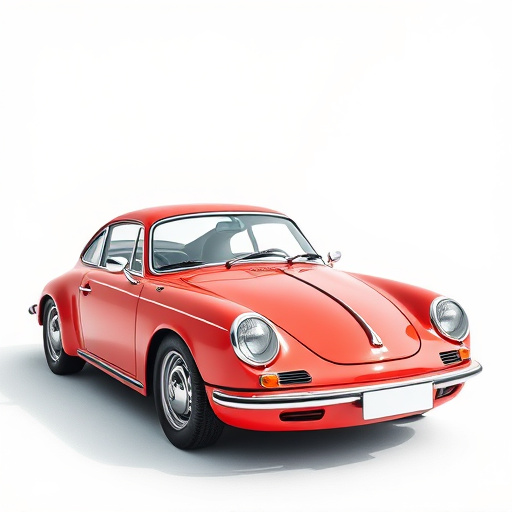

Intercooler piping, an often-overlooked component in forced induction systems, plays a pivotal role in enhancing engine performance. This article delves into the intricate details of how intercooler piping influences forced induction efficiency. We explore the impact of design and material choices, highlighting their effect on cooling capabilities. Furthermore, it discusses optimizing piping layout to minimize turbulence, ensuring optimal air-fuel mixture delivery. Understanding intercooler piping is crucial for tuning high-performance engines, making this a game-changer for automotive enthusiasts.

- Understanding Intercooler Piping and Its Role in Forced Induction

- The Impact of Intercooler Design and Material on Performance

- Optimizing Piping Layout for Maximum Efficiency and Reduced Turbulence

Understanding Intercooler Piping and Its Role in Forced Induction

Intercooler piping is a vital component in forced induction systems, playing a crucial role in enhancing engine performance. It refers to the network of tubes and components that convey compressed air from the turbocharger or supercharger back to the intake manifold. This system is designed to efficiently cool the hot air before it enters the engine, ensuring optimal combustion and maximizing power output.

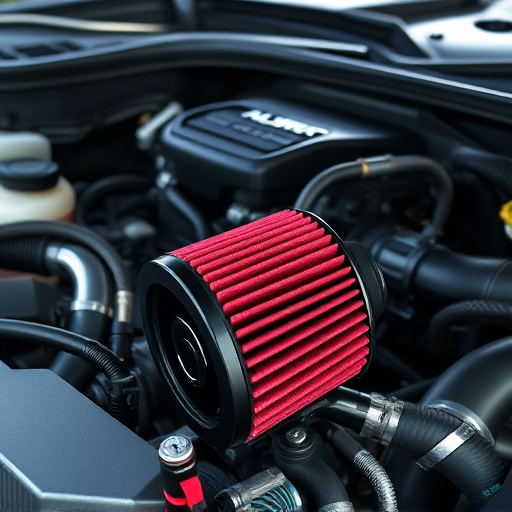

The intercooler piping acts as a vital link between the forced induction components. By optimizing airflow and minimizing temperature rise, it allows for improved air density, resulting in enhanced turbocharger or supercharger performance. This is particularly significant when paired with high-flow air filter kits and efficient air intake systems, as it ensures that the engine receives a steady supply of cool, dense air, ultimately contributing to better throttle response and increased horsepower, even when compared to exhaust mufflers.

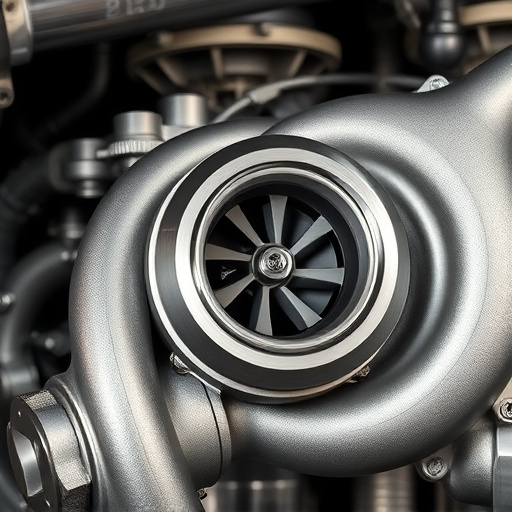

The Impact of Intercooler Design and Material on Performance

The design and material of an intercooler play a pivotal role in enhancing forced induction performance. Advanced intercooler designs, such as those with larger core sizes and optimized flow paths, significantly reduce the time it takes to cool compressed air from the turbocharger or supercharger. This rapid cooling ensures that the air remains dense and rich in oxygen, maximizing its potential for combustion. Furthermore, high-quality materials like aluminum alloys offer excellent thermal conductivity, enabling efficient heat transfer away from the hot air stream.

In addition to design and material, the integration of intercooler piping also contributes to overall performance. Optimized piping layouts minimize restrictions, ensuring swift movement of cooled air into the intake system. This seamless transition allows for a more consistent supply of cold, dense air to the engine, ultimately supporting higher power outputs and improved torque delivery, especially in high-performance vehicles equipped with powerful forced induction systems and air intake systems, as well as exhaust tips and air filter kits.

Optimizing Piping Layout for Maximum Efficiency and Reduced Turbulence

Optimizing the piping layout of an intercooler is a key aspect of enhancing forced induction performance. By carefully designing the routing and size of the pipes, engineers can achieve maximum efficiency and minimize turbulence. This involves strategic positioning to reduce pressure drops, ensuring smooth airflow from the air intake systems to the intercooler and subsequently to the engine. The goal is to create a seamless connection between components, allowing for optimal cooling without energy loss due to friction or chaotic air flow.

Consideration should also be given to integrating muffler tips and exhaust tips in a manner that supports this efficiency. Properly designed intercooler piping, in conjunction with well-tuned air intake systems and exhaust components, can lead to significant gains in engine power and performance, making it a crucial element for those seeking to push their vehicles to the limit.

Intercooler piping, an often-overlooked component in forced induction systems, plays a pivotal role in enhancing overall performance. By optimizing its design and layout, as discussed in this article, you can achieve significant gains in efficiency, reduced turbulence, and improved engine power. The choice of material and intricate design considerations are key to unlocking the full potential of intercooler piping, making it an essential element for any performance enthusiast seeking to maximize their forced induction setup’s capabilities.