Intercooler piping, a vital component in turbo and supercharger systems, optimizes engine performance by efficiently cooling compressed air. Meticulously designed for minimal pressure loss while delivering cool, dense air, durable materials like stainless steel, aluminum, or composite ensure longevity. Strategic installation considerations, including fitment, sealing, and vehicle layout, are crucial for maximizing cooling effectiveness and overall system efficiency, ultimately enhancing vehicle performance and the driving experience.

In the realm of high-performance turbo and supercharger builds, efficient cooling systems are paramount. Intercooler piping, a critical component, plays a pivotal role in enhancing engine output and reliability. This article delves into the essentials of intercooler piping basics, exploring material considerations for optimal performance and durability. We also provide valuable installation tips and best practices to ensure efficient cooling systems that excel under pressure. Understanding these key aspects can revolutionize your vehicle’s cooling dynamics.

- Understanding Intercooler Piping Basics for Turbo and Supercharger Builds

- Material Considerations for Optimal Performance and Durability

- Installation Tips and Best Practices for Efficient Cooling Systems

Understanding Intercooler Piping Basics for Turbo and Supercharger Builds

Understanding Intercooler Piping Basics for Turbo and Supercharger Builds

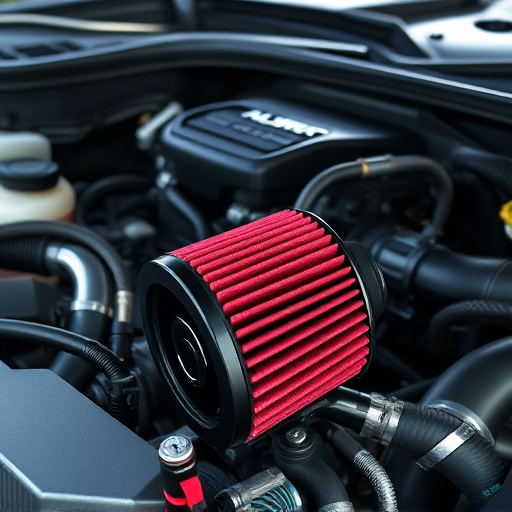

Intercooler piping is a critical component in any turbo or supercharger build, playing a vital role in enhancing vehicle performance. It involves a network of tubes designed to efficiently transfer compressed air from the turbocharger or supercharger to the intercooler, which cools the hot air before it enters the engine. This process ensures optimal efficiency and power output, as overheat can significantly degrade engine performance.

The piping system is engineered to balance pressure drop and flow rate, ensuring minimal loss in air pressure while delivering cool, dense air to the engine. Proper intercooler piping includes carefully selected materials for corrosion resistance and durability, considering both the extreme temperatures and pressures encountered in high-performance vehicles. By optimizing these factors, the overall efficiency of the turbocharger or supercharger system is maximized, contributing to improved vehicle performance and driving experience.

Material Considerations for Optimal Performance and Durability

When designing intercooler piping for turbo or supercharger builds, material considerations are paramount to achieving optimal performance and durability. The right choice can significantly impact air flow, temperature drop, and long-term reliability. Stainless steel is a popular option due to its corrosion resistance, strength, and ability to handle high temperatures, making it ideal for demanding automotive applications. Additionally, aluminum intercooler piping offers excellent heat conductivity, which aids in rapid cooling, enhancing engine performance brakes and overall efficiency.

Compared to traditional materials, modern composite materials are gaining traction for their lightweight properties and advanced durability. These innovative options can reduce weight, improve response times, and even provide better thermal insulation. Conversely, poor material selection can lead to weaknesses, such as corrosion, cracking, or warping, compromising both performance and safety, especially when combined with high-performance suspension kits and powerful brake rotors. Therefore, understanding material characteristics is crucial for constructing robust intercooler piping that seamlessly integrates with other critical components like those found in advanced suspension systems.

Installation Tips and Best Practices for Efficient Cooling Systems

When installing intercooler piping for turbo or supercharger builds, it’s crucial to follow best practices for optimal cooling performance. Start by ensuring proper fitment and sealing to prevent leaks, which can be detrimental to your engine’s health and overall efficiency. Use high-quality materials designed for automotive applications to withstand the heat and pressure generated during intense driving conditions.

Consider the layout of your vehicle’s underbody and ensure the intercooler piping doesn’t interfere with other components like cat back exhaust systems or cold air intakes. Proper routing is key; avoid sharp turns or kinks that can restrict airflow or cause damage to suspension components. Remember, efficient cooling isn’t just about having the right parts; it involves strategic installation that leverages your vehicle’s aerodynamics and structural design for enhanced performance and reliability in high-performance builds.

When designing an intercooler system for turbo or supercharger builds, attention to detail in both material selection and installation is paramount. Understanding the fundamentals of intercooler piping ensures optimal performance and longevity. By choosing the right materials and following best practices during installation, you can revolutionize your vehicle’s cooling capabilities, enhancing overall efficiency and engine health. Remember, the key to successful intercooler piping lies in prioritizing both performance and durability.