Intercooler piping is a critical component for turbocharged engines, addressing boost loss and heat soak issues. Efficient piping design quickly dissipates heat from compressed air, maintaining optimal intake temperatures and pressures. This enhances engine performance, improves cat-back exhaust response, and optimizes brake system efficiency by increasing overall engine efficiency. Optimized intercooler piping routing, diameter selection, and smooth bends minimize temperature rise, reducing heat soak and boosting fuel economy while ensuring powerful vehicle dynamics.

Intercooler piping is a crucial component in turbocharged engines, playing a vital role in reducing boost loss and minimizing heat soak. This article delves into the intricacies of boost loss and heat management in turbocharged engines, highlighting the significance of efficient intercooler piping. We explore how optimized piping design enhances heat transfer, boosts efficiency, and ultimately improves overall engine performance. Get ready to uncover the secrets behind state-of-the-art intercooler technology.

- Understanding Boost Loss and Heat Soak in Turbocharged Engines

- The Role of Intercooler Piping in Heat Transfer and Efficiency

- Optimizing Intercooler Piping Design for Maximum Performance and Reduced Losses

Understanding Boost Loss and Heat Soak in Turbocharged Engines

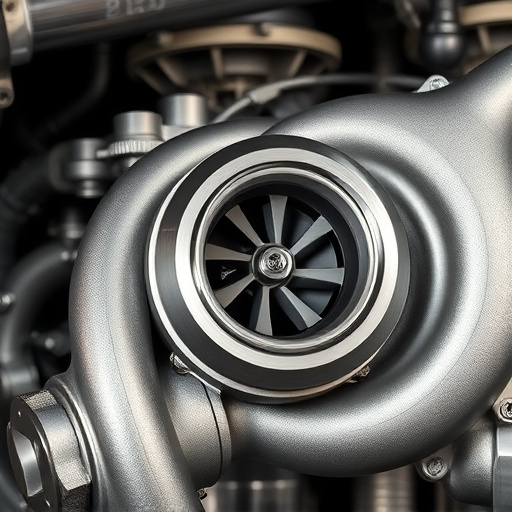

Boost loss and heat soak are significant issues faced by owners of turbocharged engines. Boost loss refers to the reduction in engine boost pressure over time during operation, leading to decreased performance and efficiency. This is primarily caused by various factors such as air leaks, inefficient charge cooling, and pressure differentials within the engine bay. Heat soak, on the other hand, occurs when excess heat from the exhaust system and other components raises the intake air temperature, reducing its density and, consequently, power output.

These issues can be mitigated with efficient intercooler piping. Intercoolers are crucial in quickly dissipating the heat extracted from compressed air, ensuring that the cooled air is delivered to the engine under optimal conditions. Well-designed intercooler piping systems enhance airflow, minimize temperature rise between the charge air cooler and the turbocharger, and help maintain boost pressure throughout the engine’s operation. By addressing boost loss and heat soak, owners can experience improved performance brakes, a more responsive cat back exhaust, and overall better brake components due to enhanced engine efficiency.

The Role of Intercooler Piping in Heat Transfer and Efficiency

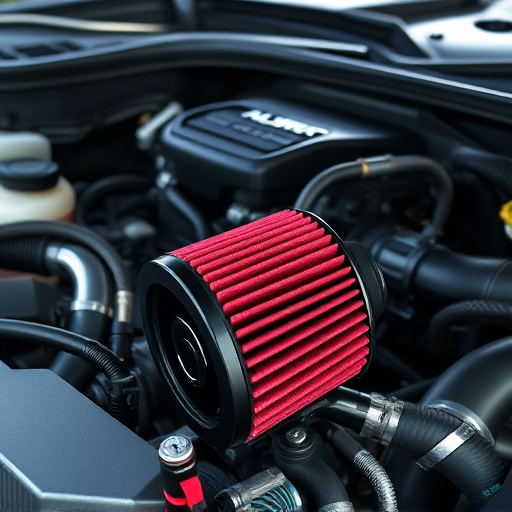

The intercooler piping plays a pivotal role in enhancing engine cooling efficiency and overall vehicle performance. It facilitates the rapid transfer of heat from the compressed air entering the turbocharger or supercharger to the surrounding environment, preventing overheating. This process is crucial for maintaining optimal boost pressure and power output, especially during demanding driving conditions.

Furthermore, efficient intercooler piping contributes to minimizing heat soak, which can negatively impact engine performance. By rapidly dissipating heat, it ensures that the compressed air remains cool, allowing for better density and more efficient combustion. This is particularly beneficial when paired with high-performance parts like advanced performance air filters and powerful performance brakes, as it helps maximize their effectiveness and overall vehicle agility.

Optimizing Intercooler Piping Design for Maximum Performance and Reduced Losses

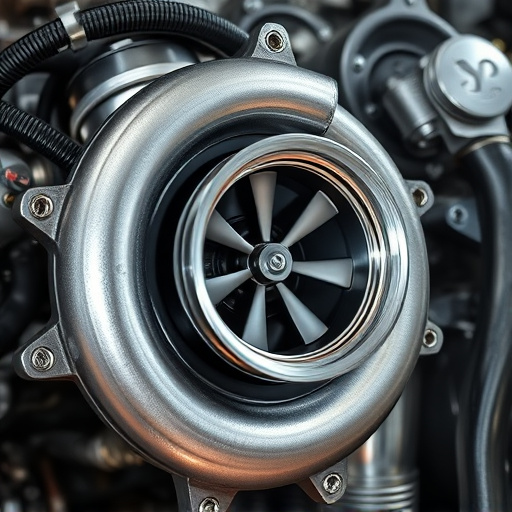

Optimizing intercooler piping design is a key aspect in enhancing vehicle performance and efficiency. By meticulously crafting the layout, engineers can significantly reduce heat soak and boost loss. This involves strategic routing to minimize temperature rise and ensure quick cooling of the compressed air. Efficient intercooler piping not only enhances engine output but also contributes to better fuel economy by minimizing energy wastage.

Furthermore, integrating features like optimized diameter selection and smooth bends can help maintain airflow efficiency. These design considerations play a crucial role in performance brakes, ensuring that the vehicle’s braking system functions optimally without any adverse effect from heat buildup. Just as efficient cooling systems benefit brake pads by preventing excessive wear, well-designed intercooler piping contributes to overall vehicle dynamics by promoting consistent and powerful performances.

In conclusion, optimizing intercooler piping design is a key strategy to reduce boost loss and heat soak in turbocharged engines. By efficiently managing heat transfer, intercooler piping enhances overall engine performance and efficiency. Understanding the principles behind boost loss and heat soak, along with tailoring intercooler piping for specific applications, ensures that modern vehicles can reach their full potential, delivering both power and fuel economy.