Custom turbo fabrication relies on intercooler piping to optimize engine performance by managing air pressure and temperature. Efficient design and durable materials ensure maximum power output, fuel efficiency, and system reliability. Engineers must balance routing, component placement, and integration with other systems for optimal airflow. Precise calculations and consideration of unique vehicle specs result in powerful, efficient turbocharging solutions that meet client expectations.

“In the realm of custom turbo fabrication, efficient cooling is paramount. ‘Intercooler Piping Required’ explores the intricacies of this vital component for high-performance vehicles. From understanding the essentials of intercooler piping to designing tailored layouts, this guide illuminates key considerations. We delve into best practices and potential challenges, offering valuable insights for professionals navigating the intricate world of custom turbo projects. Enhance your knowledge on intercooler piping today.”

- Understanding Intercooler Piping Essentials

- Designing Custom Piping Layouts

- Fabrication Tips and Potential Challenges

Understanding Intercooler Piping Essentials

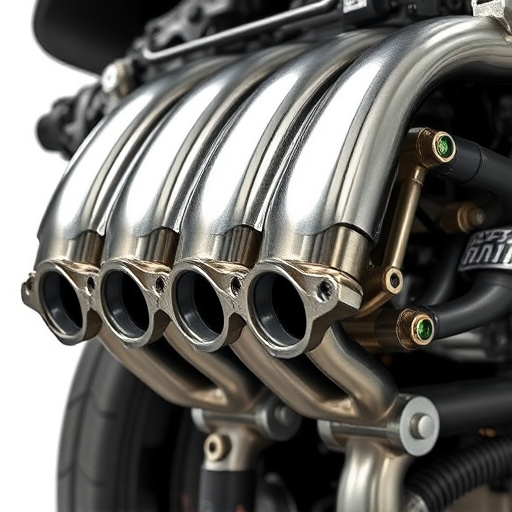

Intercooler piping is a vital component for custom turbo fabrication projects, playing a crucial role in maintaining optimal engine performance. Understanding its essentials is key to achieving efficient cooling and overall system harmony. The intercooler acts as a vital intermediary, reducing air pressure and temperature between the compressor and the intake manifold. This process ensures that compressed air enters the engine at an ideal temperature, maximizing power output and fuel efficiency.

When fabricating or upgrading a turbo system, careful consideration must be given to the design and installation of intercooler piping. High-flow, durable pipework is essential to handle the increased airflow and pressure. Integrating intercooler piping with other components like air filter kits and exhaust tips requires precision engineering to maintain airflow efficiency and prevent restrictions that could hinder engine performance. Ensuring proper cooling enhances turbocharger reliability and longevity, thereby fostering a robust and efficient power enhancement system.

Designing Custom Piping Layouts

When designing custom piping layouts for intercooler systems, engineers and fabricators must consider several factors. The primary goal is to ensure optimal airflow while maintaining efficient cooling. This involves strategic routing of pipes, placement of components like heat exchangers and diverters, and coordination with other systems such as cold air intakes and exhaust tips. A well-designed intercooler piping layout not only enhances the performance of high-performance parts but also ensures reliability under extreme conditions.

Custom piping layouts require careful planning to accommodate unique vehicle architectures and engineering specifications. Integrating intercoolers seamlessly into the overall cooling system necessitates precise calculations for flow rates, pressure drops, and temperature differentials. By balancing these elements, fabricators can deliver a powerful yet efficient turbocharging solution that meets or exceeds client expectations, particularly when paired with other performance-enhancing components like high-flow fuel injectors and advanced ignition systems.

Fabrication Tips and Potential Challenges

When fabricating a custom turbo setup, paying close attention to the intercooler piping is paramount. The intricate network of pipes responsible for cooling high-pressure air from the turbocharged engine needs meticulous design and construction. Incorporate robust materials like aluminum or stainless steel, ensuring proper joint sealing to prevent leaks that could prove detrimental to engine performance.

Navigating potential challenges requires an understanding of flow dynamics. Balancing pressure differentials across the intercooler core while integrating seamlessly with other components like intake manifolds, exhaust mufflers, and suspension systems is crucial. Careful planning is essential to avoid constrictions or kinks in the piping that could restrict airflow, undermining the system’s overall efficiency.

When embarking on custom turbo fabrication projects, understanding and meticulously planning intercooler piping is paramount. By mastering the essentials, designing efficient layouts, and being aware of potential challenges, you can ensure optimal performance and reliability in your vehicle’s cooling system. Intercooler piping, though intricate, is a crucial component that contributes to the overall success of any custom turbo build.